How do they shell corn on the cob?

Over a most excellect lunch, containing, not surprisingly corn onthe cob, the question arose about how the separation of kernels from the cob(or ear) occured. It seems that this question has been pondered and researched already by the google answers guys.

The actual page is this http://answers.google.com/answers/threadview?id=145556

However below is a summary.

Firstly, the the corn on the cob is harvested. This is done either mechanically or manually but the whole corn on the cob and husk is picked. These are taken to the processing plant where a machine machanically slices off the corn.

The machines slice off the base of the ear, and remove the husk off the ear with rollers without

damaging the kernels.

"The husked ears drop onto a belt, and workers

inspect the ears and feed them tip first into the cutting knives. The 4 or 5 knives are mounted in a round holder which allows the knives to open up. The knives have a 90 deg bend so the tips, which are curved, are parallel to the cob and form a circle. They are very sharp, turn very fast, and open and close depending on the diameter and shape of the cob. They cut very fast, very cleanly. Cobs shoot straight though and go to the waste pile, the cut corn falls onto another

conveyor. Husks and cobs are chopped and made into silage for cattle feed. I worked several summers at a Green Giant processing plant, canning peas and corn. Only field corn and sweet corn seed is allowed to dry in the field before picking." Evidently some mechanical guides allow for the awkward shape of the corn to prevent too much from being sliced off.

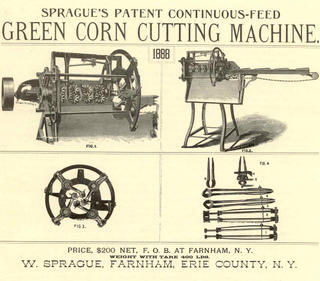

Below is a picture of a 19th century corn cutting machine made by Welcome Sprague in Farnham, New York.

This feeds corn along a converyor belt into a series of rotaing knives which slice off all the kernels and with the motion of cutting off the kernels, twists the ear on its axis to allow the bit sitting on the belt to be shorn of kernels as well. It seem that this is one of the best methods of skinning kernels, although i am sure a gravity drop machine would be more efficient, removing the need of the initial conveyor belt enabling the machine perhaps to be hopper fed, and, via a griddle underneath the machine would conserve energy by simple sorting of ears and kernels.

0 Comments:

Post a Comment

<< Home